Just not sure about Metal TAGS?

So You need to purchase tags for some kind of application, but you’re not sure exactly which kind – that’s why you’re here. This article will help you to decide on what tag material or substrate will best fit your requirements. We will start with a few basic questions to help determine the basis of what you need. We will discuss the following materials to offer guidance that pertains to your immediate tagging need and requirement. When determining the ideal substrate for crafting label tags for a company, careful consideration of various factors is paramount. The choice of substrate significantly influences the tag’s durability, appearance, and overall effectiveness.

Factors such as the intended use, environment, and branding aesthetic play crucial roles. For instance, if the tags are intended for outdoor use, substrates like weather-resistant plastics or metals such as aluminum are excellent choices due to their resilience against harsh elements. In indoor settings, paper-based substrates might be suitable, especially when a natural or eco-friendly appeal is desired.

Additionally, the printing method and the need for customization should guide the substrate choice; materials like vinyl, polyester, or coated paper work well for digital or offset printing, offering a polished finish. Furthermore, considering the company’s values, budget constraints, and the recyclability of the chosen substrate aligns the production process with environmental responsibility. Careful evaluation of these aspects ensures that the selected substrate aligns perfectly with the company’s branding objectives while guaranteeing longevity and visual appeal for the label tags.

Durability

Are your tags going to be subjected to the harsh outdoor elements? Maybe they are simply being installed onto a control panel or power system that is kept indoors and within a climate controlled environment. Metal Tags are almost always a sure bet.

Anodized Aluminum Metal Tags VS. Stainless Steel Metal Tags

They are known as the best two materials to produce tags with in regards to harsh environments. Generally speaking I usually sway towards Aluminum Metal Tags as they are light-weight and will not corrode. Stainless Steel Metal Tags have been known to contain corrosive properties over long periods of time based on various chemicals, temperature and especially exposure to nature.

Aluminum Metal Tags & Data Plates

Aluminum Metal Tags can be supplied in varying thickness from the ultra thin .003″ – .25″. When produced in a thin format such as .003″ Aluminum Metal Tags extremely ideal for electrical equipment and machinery that may require barcoding, variable data, or information that specifically applies to inventory and tracking. Proper examples would be power supplies, small motors, pumps, laptops or tablets issued in bulk volume throughout an organization. Thin Aluminum labels and Metal Tags are difficult to remove and can be produced in a tamper-proof format to help discourage theft.

.003 Aluminum Metal Tags are ideal for surfaces that are con-caved or rounded as the thin material supplies the ability for your labels or tags to wrap AROUND an object such as a small Capstan motor or pump.

Aluminum Metal Tags ranging from a thickness of .020 – .25″ are almost all equally durable provided they are directly mounted to a flat surface with screws or bolts. High-Strength Adhesives may be used but to retain the ultimate durability we always encourage our customers to install with hardware and not adhesive.

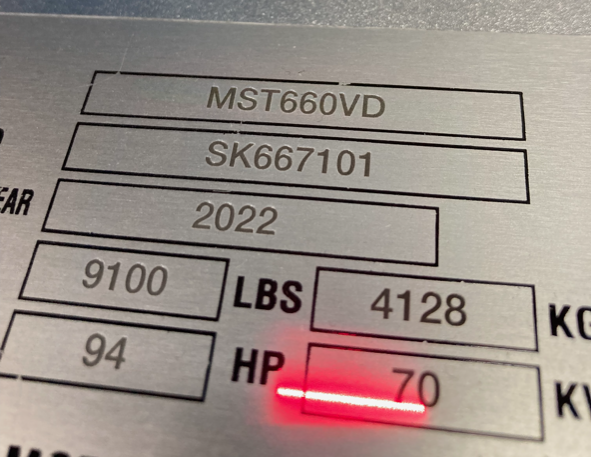

Stainless Steel Metal Tags & Data Plates

Stainless Steel Metal Tags can be supplied in varying thickness from .020 – .5″ in thickness. Metal Tags and Data plates that are manufactured out of Stainless Steel are ideal for harsh environments where they are subjected to physical abuse and chemical abuse. (physical impact or solvents/chemical agents).

Proper application examples would be motors, boiler systems, heat exchangers, power systems or engine parts. Stainless steel Metal Tags do not contour very well, but it sure does hold up and is easy to clean. A large majority of Metal Tags and Data plates are made from Stainless Steel for reasons of durability, aesthetics and sanitary properties. It is very easy to wipe down stainless and it cleans up nicely 🙂

Metal Tags created from Brass can be supplied in varying thickness from .020 – .1875″ in thickness as it’s much harder to cut with a laser. Valve tags are often manufactured out of Brass and are ideal for harsh environments where they are subjected to physical abuse and chemical abuse. However Brass Tags are known to tarnish over time into a red or greenish color.

Proper application for Brass Tags would be valves, pumps, boiler systems, heat exchangers, or power systems. Brass does not contour very well around a part due to the thicker nature, but it sure does hold up and is easy to clean. A large majority of Metal Tags are made from Brass for reasons of durability, aesthetics and sanitary properties.

Plastic Tags & Signs

Plastic can be supplied in varying thickness from .020 – .1875″ in thickness and it is very easy to cut with a laser. Most indoor tags are often manufactured out of Plastic and they can withstand physical abuse and easily be removed and reapplied when needed. However Plastic tags are sensitive to harsh solvents and chemicals which can cause imperfections in the background color of the tag to “bubble or smear”.

Plastic Tags are great because we supply them with adhesive or custom cut holes very easily into the corners/sides of the material. We can easily laser-cut holes in various places if you require tags for control panels for knobs, buttons or switches. Proper application for Plastic Tags would be breaker boxes, valves, pumps, control panels, boiler systems, electrical components, or power systems.

Plastic tags can contour very well around a part in thinner formats like .020″ or .03125″. A majority of tags are made from plastic for reasons of durability, aesthetics and sanitary properties. It is very easy to wipe down plastic with alcohol and it cleans up nicely 🙂

∇ CONTACT US ∇

Email Us Here!

–OR–

(800) 482-1553

Monday – Friday – 9:00 am – 5:00 pm EST

Check out our Satellite Sites: